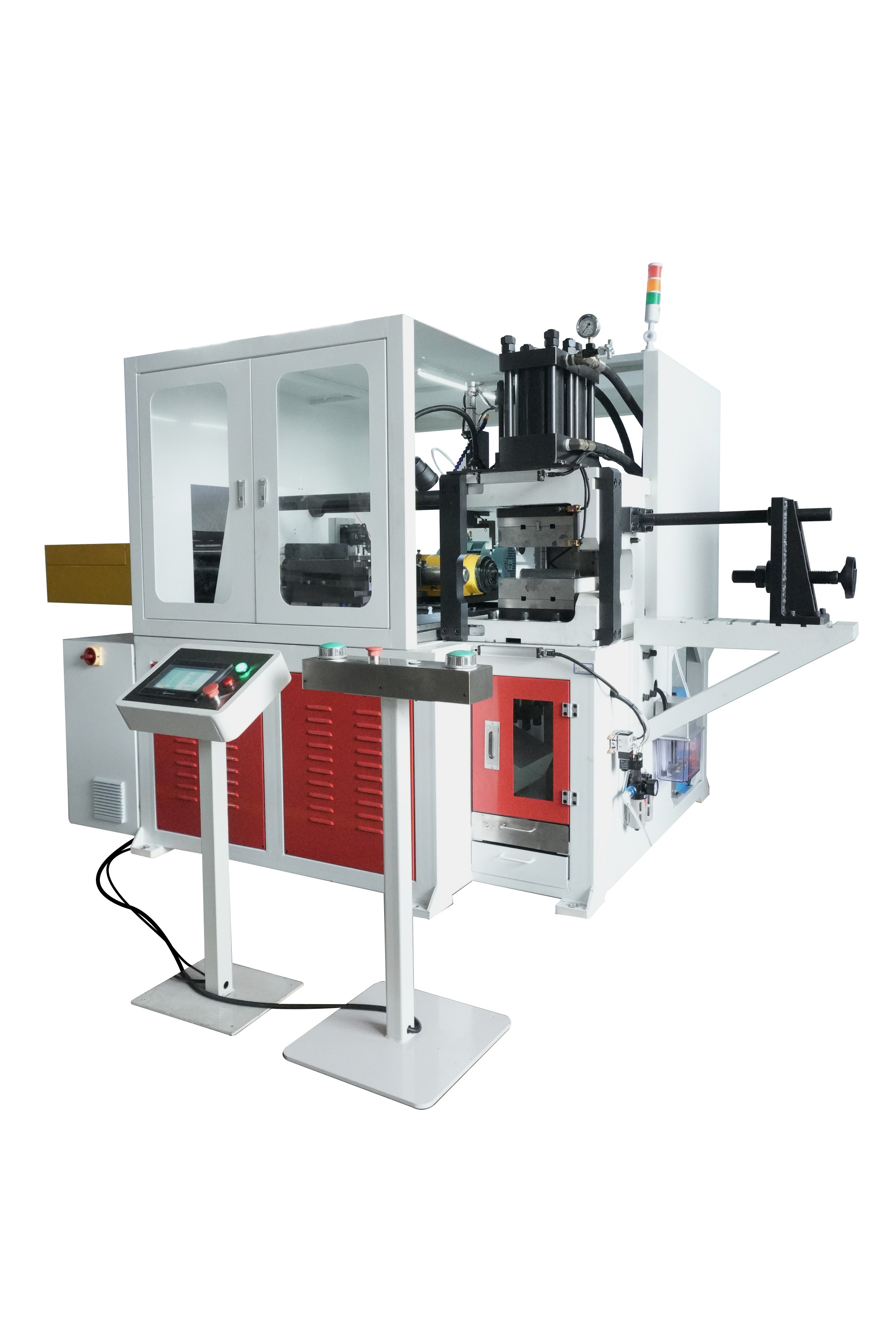

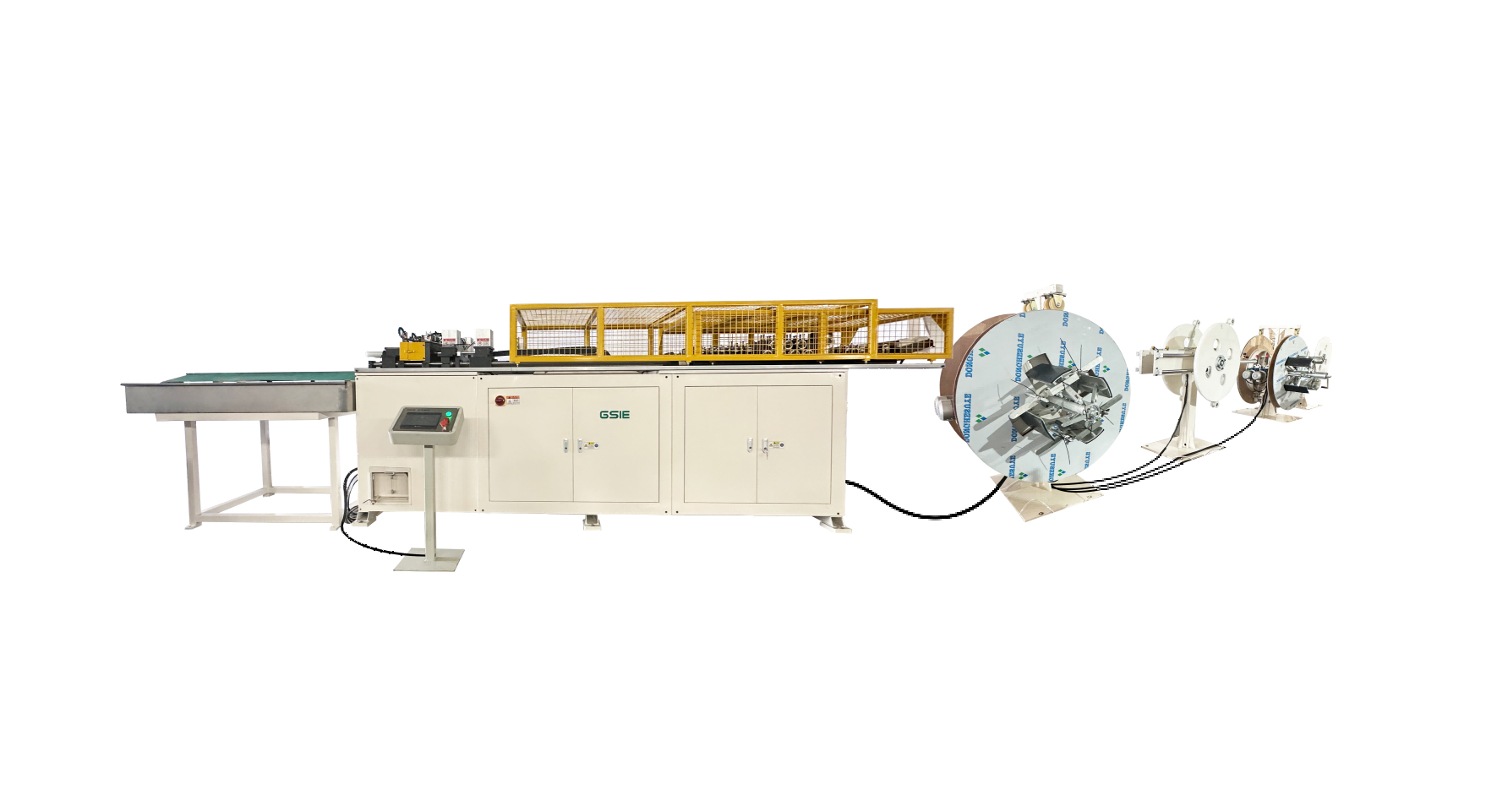

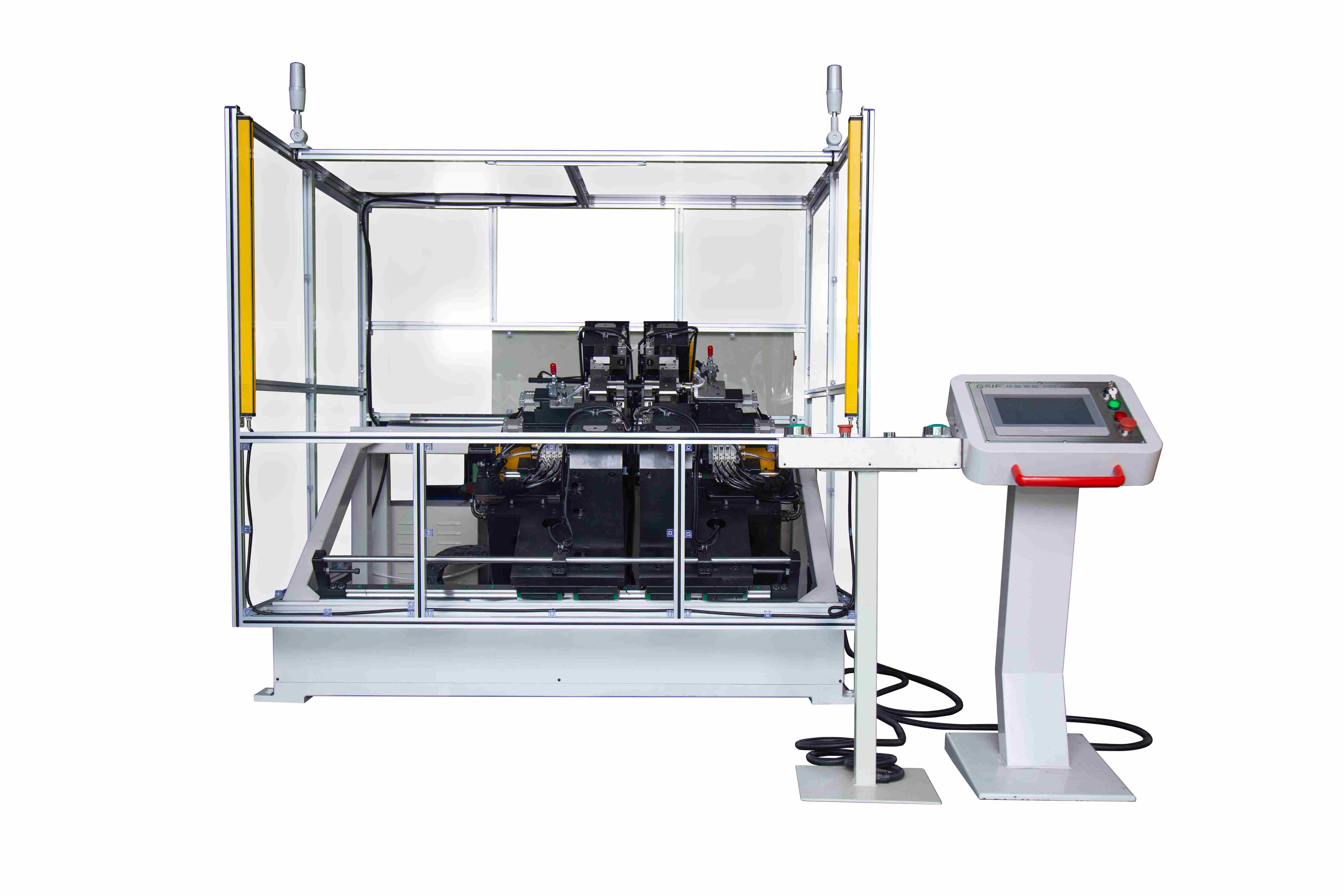

Single-Head Chamfering Machine(DJ-50)

A single-spindle chamfering machine is specialized equipment for processing the end faces, outer edges, and inner corners of pipes. It features automatic feeding and automatic engagement/retraction of the cutting tool, delivering high speed and superior precision. This machine is ideally suited for the batch processing of pipe fittings.